Need help?

Xomox Butterfly And Diaphgram Valve Supplier, Stockiest, Dealer, Trader, Distributors

Valve Manufacture In Saudi Arabia Supplier, Stockiest, Dealer, Trader, Distributors

Bellow Seal Valve Manufacturer Supplier, Stockiest, Dealer, Trader, Distributors

Valves Factory In China Supplier, Stockiest, Dealer, Trader, Distributors

Gate Valve Supplier, Stockiest, Dealer, Trader, Distributors

Globe Valve Supplier, Stockiest, Dealer, Trader, Distributors

Butterfly Valve Supplier, Stockiest, Dealer, Trader, Distributors

Pneumatic Butterfly Valve Supplier, Stockiest, Dealer, Trader, Distributors

Swing Check Valve Supplier, Stockiest, Dealer, Trader, Distributors

Plug Valve Supplier, Stockiest, Dealer, Trader, Distributors

Cryogenic Valve Supplier, Stockiest, Dealer, Trader, Distributors

Relief And Safety Valve Supplier, Stockiest, Dealer, Trader, Distributors

Diaphragm Valve Supplier, Stockiest, Dealer, Trader, Distributors

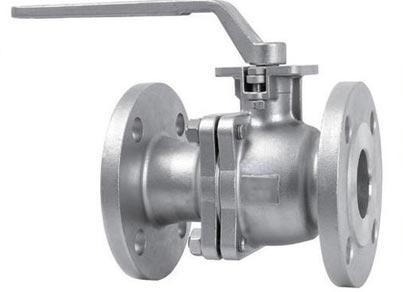

Ball Valves Supplier, Stockiest, Dealer, Trader, Distributors

A 2 Piece Ball Valve is a type of valve commonly used for various industrial applications, providing excellent shutoff capabilities and control of fluid flow. The valve consists of two main parts—the body and the end piece, which allows for easy maintenance and repair without dismantling the entire valve from the pipeline. This design is often favored for its simplicity, cost-effectiveness, and efficient performance. The Threaded Ball Valve is a variant featuring threaded connections for easier installation in piping systems. It is commonly used in low-pressure applications for fluid and gas control. A Floating Ball Valve features a ball that is not fixed but "floats" within the valve body. The fluid pressure helps seal the ball against the downstream seat, ensuring tight sealing and preventing leaks.

For high-temperature and abrasive environments, a Metal-to-Metal Ball Valve is designed with metal seats and a metal ball, making it highly durable and able to withstand harsh conditions. The Jacketed Floating Ball Valve is equipped with a jacket around the valve body, allowing heating or cooling media to pass through. This type of valve is useful in industries where temperature control of the flowing media is critical, such as chemical or petrochemical processes. An FEP Lined Ball Valve is lined with fluorinated ethylene propylene (FEP), providing corrosion resistance and making it suitable for handling aggressive chemicals and acids. It offers a cost-effective solution for corrosive environments.

A Spring-Loaded Trunnion Mounted Ball Valve is designed with a spring mechanism that aids in the movement of the ball, ensuring smooth operation even under high pressure. The trunnion-mounted design provides additional support to the ball, improving durability and reducing wear. Hydraulic Ball Valves are engineered for high-pressure hydraulic systems. These valves are robust and reliable, allowing precise control of hydraulic fluids. An API 6A Ball Valve meets the stringent standards set by the American Petroleum Institute (API) for use in oil and gas wellhead applications. These valves are designed to withstand extreme pressure and temperature conditions. Finally, Top Entry Ball Valves offer easy access to the internal components without the need to remove the valve from the pipeline. This feature is highly beneficial for maintenance and repair, reducing downtime in critical applications.

| Specification | Description |

|---|---|

| Type | 2 Piece Ball Valve |

| Connection | Threaded Ball Valve |

| Design | Floating Ball Valve |

| Material | Metal-to-Metal Ball Valve |

| Special Feature | Jacketed Floating Ball Valve |

| Lining | FEP Lined Ball Valve |

| Mechanism | Spring Loaded Trunnion Mounted Ball Valve |

| Application | Hydraulic Ball Valve |

| Standards | API 6A Ball Valve |

| Access | Top Entry Ball Valve |